Why selecting the appropriate bearings is important for machines?

Selecting the appropriate bearing for equipment that needs frictionless power transmission is a crucial process that involves various factors. This process encompasses aspects such as the mechanical operation’s load type and the maintenance necessary for the bearing’s efficient operation. As a supplier of bearings based in Kolkata, Santiniketan Enterprises (SantEnt) has a wealth of knowledge and expertise to guide you in selecting the right bearing for your machine application. Whether you require frictionless transmission for HVAC, food processing, or other critical applications, SantEnt can assist you in making an informed decision.

Tips for Selecting the Appropriate Bearings for Your Machine’s Needs

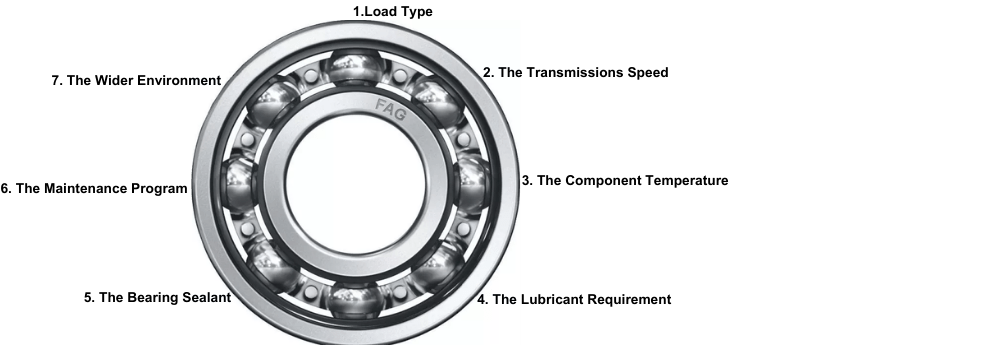

7 deciding factors you should be aware of when selecting the correct bearing:

1. The Load Type

Before acquiring a bearing, it is important to understand three types of loads:

- Radial Loads: These forces act perpendicular to the rotating shaft.

- Combined Loads: These loads involve a combination of both radial and axial forces or can be interchangeable between the two.

- Axial Loads: These forces are parallel to the rotating shaft.

2. The Transmissions Speed

- Bearings must be chosen based on their ability to withstand varied speeds and temperatures

- Roller bearings are more effective for slower transmissions and can handle heavier loads..

- Precision bearings are necessary for high-speed applications to prevent issues like vibrations and increased wear.

- Ball bearings are suitable for higher rotational speeds.

3. The Component Temperature

- Lubricant compatibility: Ensure the lubricant used in the bearing is suitable for high-temperature applications and does not evaporate quickly.

- Consider operational temperature: Fluctuating and extreme temperatures can impact bearing performance.

- Material selection: Choose bearings that can withstand high-temperature stress without deformation or failure.

4. The Lubricant Requirement

- Lubrication is essential for smooth and efficient power transmission in bearings.

- Three types of lubricants to consider: grease, petroleum-based oil, and synthetic oil.

- Choose the lubricant based on the specific needs and requirements of your machine equipment.

- Each lubricant type has unique properties and maintenance requirements.

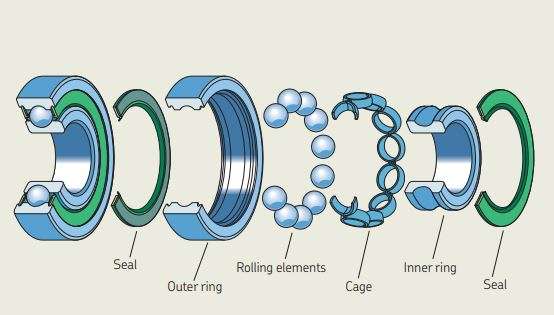

5. The Bearing Sealant

- Bearing sealants reduce lubricant contamination and evaporation.

- Two primary types of bearing sealants: integrated shields and rubber seals.

- Integrated shields are made of the same materials as the bearing and provide protection.

- Rubber seals are suitable when high temperatures and speeds are not a concern.

6. The Maintenance Program

- Maintenance is essential for uninterrupted operations.

- Three types of maintenance: preventive, predictive, and reactive.

- Bearings using oil-based lubricants often need more frequent maintenance.

- Lower-cost bearings may require more preventive and predictive maintenance, leading to higher long-term costs.

7. The Wider Environment

- Consider the operating environment when selecting bearings for your machine application.

- Choose bearings that can withstand the specific conditions of the operating environment to ensure optimal performance and longevity.

- Harsh environments require special bearing materials, lubricants, and shields.

From where we should choose the Appropriate Bearing for Your Machinery

Santiniketan Enterprises, also known as SantEnt, has been in operation since 1977. We are known for Distributing high-quality Industrial products to customers in many countries across six continents. We deal in over 50 globally renowned brands which manufacture industrial spares and power transmission solutions like bearing, belts, maintenance products and related accessories

SantEnt is dedicated to providing top-quality products and service to its customers.