About Bearing Materials:

It is essential to choose the right bearing for industrial applications in order to maintain effective production, reduce operational disruptions, establish dependable maintenance protocols, and increase the operational lifespan of machinery.

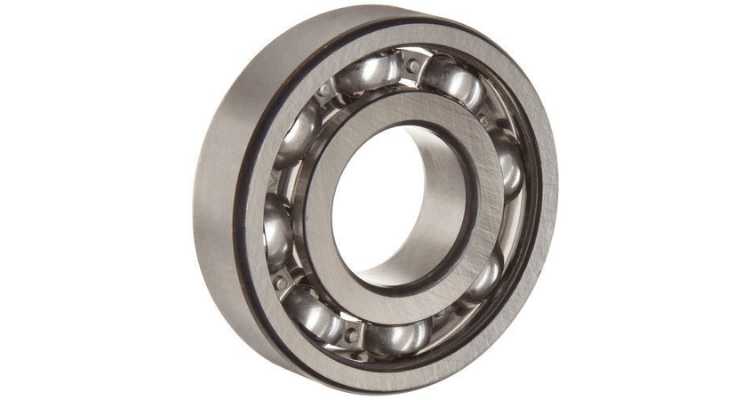

In essence, properly installed roller bearings and ball bearings are necessary for almost every mobile component within a device, whether it be an automobile or the machinery in a factory. These components serve to minimize friction, enhance movement smoothness, optimize automation-related expenses, and enhance the overall durability of the mobile components.

SantEnt has extensive experience guiding you through the process of choosing appropriate bearing components and materials suited to your machinery requirements as the official bearing provider in India.

Development Of Bearings Over the Years:

Surprisingly, the concept of achieving smoother movement by reducing friction through the use of a ‘bearing’ predates the invention of the wheel by a significant margin. In fact, it can be considered a precursor to the wheel.

Cave paintings found across the globe depict the utilization of wooden logs and fallen trees to transport heavy objects between two points. As these wooden logs rolled across the ground, heavy items were pushed along a series of logs that were continually placed in front of each other until the destination was reached.

This practice was remarkably common for many centuries and was even integrated into the innovations of civilizations like the Ancient Egyptians. Wooden bearings were employed alongside various liquids to act as lubricants, predating the introduction of new metals like zinc and bronze. However, these materials lacked the necessary strength and capabilities to serve as effective bearings.

Nonetheless, with the onset of the industrial age, a period marked by advancements in metalworking techniques and the popularity of steel as an industrial material, significant changes occurred. In 1794, an individual named Philip Vaughan obtained a patent for a design that closely resembled the ball bearing we are familiar with today.

Why Choosing Right Bearing Components and Materials is Important?

We are well aware of the critical relevance of identifying the right jigsaw pieces that result in cost savings and increased productivity in an industrial setting.

When purchasing supplies from the Indian provider of bearings, the same rule applies. The choice of suitable bearing components and materials is straightforward when industrial applications are properly considered.

Neglecting the right fit of ball bearings and roller bearings may lead to lower productivity, unneeded idle times, increased maintenance requirements, friction-related harm to surrounding parts, and even the potential for equipment failure.

To avoid seeing rolling contact fatigue (RCF) and damage from incorrect bearing components and materials, the following considerations should be met:

- Load: In order to perform effectively and last the intended amount of time, a bearing must be able to support the anticipated pressure and weight of the radial load, axial load, and combined load.

- Speed: Machines that operate at high speeds require speed-specific bearings that can withstand the additional force applied to the bearing in motion.

- Temperature: A ball bearing must possess adequate room to accommodate thermal expansion and the consequent generation of frictional heat. Lack of congruent contact between the ball bearing and the attachment has the potential to amplify friction and heat transfer between the components.

- Sealing: Ensuring effective sealing of the bearing is essential for preserving appropriate lubrication levels and minimizing the ingress of debris into the bearing components and materials. In environments where a significant amount of debris is generated, opting for shielded sealing is advisable.

- Maintenance: Selecting the appropriate ball bearing or roller bearing involves aligning the maintenance needs with or surpassing the current maintenance protocol in place. Striking a balance between the bearing’s cost and its lifespan performance can play a crucial role in preventing costly periods of inactivity.

Types of Bearing Materials:

As the industrial revolution introduced steel bearings, significant advancements have followed in the realm of diverse materials.

Steel is still typically the material of choice for making both the rolling components and the rings of ball bearings and roller bearings. Nevertheless, certain industrial applications necessitate different qualities including improved corrosion resistance, decreased porosity, cost effectiveness, resistance to seizing, lightweight characteristics, and increased durability.

Consequently, the following bearing materials are selected based on the specific mechanical procedures:

1. Carbon Steel Bearings

Carbon steel bearings are a type of bearings that are manufactured using carbon steel as the primary material. Carbon steel is an alloy of iron and carbon, often with small amounts of other elements, which makes it a widely used material in various industries due to its desirable properties. When applied to bearings, Carbon steel offers several benefits:

- Cost-effectiveness

- Strength and Durability

- Corrosion Resistance

- Wide Availability

- Compatibility

- Moderate Thermal Conductivity

- Machinability

- Wear Resistance

Despite these benefits, it’s important to note that carbon steel bearings might not be suitable for all applications. In environments with extremely high corrosion, extreme temperatures, or specific material compatibility requirements, other bearing materials such as stainless steel, ceramic, or specific alloys might be more appropriate.

When considering carbon steel bearings, it’s crucial to assess the specific operational conditions, load requirements, and environmental factors to determine whether carbon steel bearings are the right choice for the intended application.

2. Chrome Steel Bearings

Chrome steel bearings, also known as chrome alloy or chrome steel ball bearings, are a type of bearing made from a specific type of steel alloy known as chrome steel. These bearings are widely used in various industries and applications due to their specific properties and advantages. Here are some details about chrome steel bearings and their benefits:

Composition: Chrome steel is an alloy primarily composed of iron, chromium, and carbon, along with other trace elements. The high chromium content provides corrosion resistance and hardness to the steel. Chrome Steel Bearings offers several benefits:

- High Corrosion Resistance

- High Hardness

- Wear Resistance

- Smooth Surface Finish

- Moderate Cost

- Wide Temperature Range

- Compatibility

- Reliability

It’s important to note that while chrome steel bearings offer many benefits, they might not be suitable for every application. For extremely demanding environments or specialized needs, other bearing materials such as ceramics, stainless steel, or specific alloys might be better options. When selecting bearings, it’s essential to consider factors such as load capacity, speed, operating conditions, and environmental factors to ensure the optimal choice for the intended application.

3. Stainless Steel Bearings

Stainless steel bearings are a type of bearing that is crafted from stainless steel, a corrosion-resistant alloy that contains chromium, nickel, and other elements. These bearings are particularly advantageous in applications where corrosion resistance and hygiene are essential. Here’s a closer look at stainless steel bearings and their benefits:

- Corrosion Resistance

- Hygiene and Cleanliness

- Longevity

- Temperature Tolerance

- Non-Magnetic

- Aesthetic Appeal

- Reduced Maintenance

- Compatibility

While stainless steel bearings offer numerous advantages, they might have higher initial costs compared to traditional steel bearings. Therefore, it’s important to consider factors such as the specific application requirements, load capacity, operational conditions, and budget when selecting the appropriate bearing type.

4. Ceramic Bearings

Ceramic bearings are a specialized type of bearings that utilize ceramic materials, such as silicon nitride (Si3N4) or zirconia (ZrO2), for their rolling elements and often for the bearing races as well. These bearings offer several unique benefits due to the properties of ceramic materials. Here’s an overview of ceramic bearings and their advantages:

- High Hardness

- Low Friction

- Corrosion Resistance

- High Temperature Capability

- Hybrid Designs

- Reduced Lubrication Needs

- Insulating Properties

- Performance Enhancements

Ceramic bearings are often chosen for applications where high performance, precision, and specific material properties are critical. These applications can range from industries such as aerospace, medical equipment, high-performance bicycles, and certain industrial machinery.

It’s important to note that while ceramic bearings offer several advantages, they may come with higher upfront costs compared to traditional steel bearings. When considering ceramic bearings, it’s crucial to assess the specific requirements of the application, such as load capacity, speed, operating conditions, and budget, to determine if the benefits of ceramic materials align with the intended use case.

5. Polymer Plastic Bearings

Polymer plastic bearings, also known as plastic or polymer bearings, are a specialized type of bearings made entirely or partially from various polymer materials. These bearings offer distinct advantages due to their unique characteristics and properties. Here’s an overview of polymer plastic bearings and their benefits:

- Low Friction

- Corrosion Resistance

- Chemical Compatibility

- Lightweight

- Electrical Insulation

- Noise and Vibration Damping

- Non-Magnetic

- Cost-Effectiveness

Polymer plastic bearings find applications in industries such as food and beverage, pharmaceuticals, medical equipment, automotive, electronics, and more. However, it’s important to note that plastic materials might have certain limitations, such as lower load capacities compared to metal bearings and sensitivity to high temperatures or abrasive conditions.

When considering polymer plastic bearings, carefully evaluate factors such as load capacity, operating conditions, temperature range, chemical exposure, and budget to ensure they are suitable for the intended application. Additionally, ensure that the specific polymer material chosen aligns with the required properties for the given application.

6. Hybrid Bearings

Hybrid bearings are a type of bearings that combine elements from different materials to leverage the advantages of each material. Typically, hybrid bearings feature ceramic rolling elements (balls) combined with steel inner and outer races (rings). This combination offers a balance between the unique properties of ceramic and steel materials, providing enhanced performance in certain applications. Here’s an overview of hybrid bearings and their benefits:

- High Speed Capability

- Low Friction

- Corrosion Resistance

- Electrical Insulation

- Enhanced Rigidity

- Lightweight

- Quiet Operation

- Longer Lifespan

Hybrid bearings are commonly employed in industries where performance, precision, and reliability are critical. Applications include aerospace, robotics, medical devices, high-performance bicycles, and specialized machinery.

It’s essential to consider the specific operational requirements, load capacities, speed limitations, and environmental conditions when selecting hybrid bearings. While they offer several advantages, hybrid bearings might have higher costs compared to conventional steel bearings. Thus, a thorough evaluation of the application needs will help determine whether the benefits of hybrid bearings align with the intended use case.

Selecting the Appropriate Bearing Material for Your Machinery

Santiniketan Enterprises, also known as SantEnt, has been in operation since 1977. We are known for Distributing high-quality Industrial products to customers in many countries across six continents. We deal in over 50 globally renowned brands which manufacture industrial spares and power transmission solutions like bearing, belts, maintenance products and related accessories

SantEnt is dedicated to providing top-quality products and service to its customers.