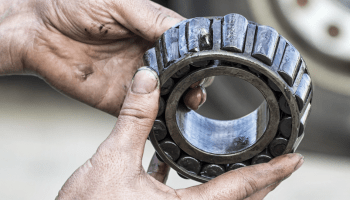

Roller bearings are diminutive elements within a mechanical operation that involve combining two parts with minimal resistance to friction. Despite being economical components, their malfunction can be the primary source of lengthy periods of inactivity, incurring substantial costs.

The crucial aspect of this reduced frictional resistance plays a pivotal role in upholding the consistency of infrastructure while minimizing evaluations for deterioration, a ball bearing or roller bearing comprises an inner ring with rotating components and an outer ring attached to stationary features.

It’s not surprising that the juxtaposition of these two distinct components can lead to the breakdown and failure of roller bearings and ball bearings. Typically, these malfunctions arise due to factors such as rust, aging, excessive loads, or insufficient lubrication. However, it’s imperative to identify signs of failure in all aspects of roller bearing operation in order to take appropriate measures and execute essential proactive, anticipatory, and responsive maintenance protocols, thereby reducing expenses and periods of downtime.

6 Common Factors for the failure of Roller Bearings:

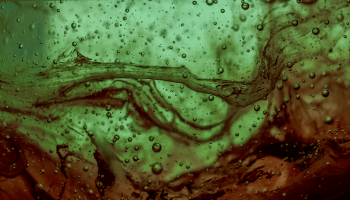

1. Lubrication Contamination

Lubrication contamination can significantly impact roller bearings by causing accelerated wear, reducing operational efficiency, and ultimately leading to premature failure. Contaminants such as dirt, dust, debris, moisture, or foreign substances that infiltrate the lubricant surrounding the roller bearings can have several negative effects:

- Abrasive Wear: Abrasive contaminants cause friction and abrasion between bearing surfaces by acting as abrasive particles.

- Increased Friction: Contaminants reduce the oil’s or grease’s ability to lubricate, increasing friction and generating more heat while the machine is operating.

- Corrosion: Some contaminants can be corrosive, causing chemical reactions that deteriorate the bearing surfaces, leading to rust, pitting, and weakening of the structure.

- Clogging and Blockage: Some contaminants have the potential to be corrosive, which can result in chemical reactions that damage the bearing surfaces and weaken the structure by causing rust and pitting.

- Lubricant Breakdown: The lubricant’s effectiveness can be harmed by contaminants, which also affects its capacity to form a protective film between the rolling elements.

How to prevent failure from Lubrication Contamination on Roller Bearings

- Preventive Measures:

- To reduce the introduction of contaminants, keep the working environment clean.

- Use appropriate sealing techniques to keep outside debris from getting inside the bearing.

- Seals should be regularly inspected and replaced to maintain their effectiveness.

- Proper Lubrication Practices:

- Use high-quality lubricants suitable for the bearing’s operating conditions.

- For information on lubricant type, quantity, and replenishment intervals, consult the manufacturer.

- Regular Maintenance:

- Set up routine cleaning and maintenance to get rid of any accumulated contaminants from the lubricant and bearing surfaces.

- Filtration Systems:

- Filtration systems that work well should be used to clean the lubrication system of contaminants.

- Correct Handling:

- To prevent introducing additional contaminants, always use clean hands and tools when handling bearings.

- Lubricant Analysis:

- Check lubricant samples for contamination or deterioration on a regular basis.

- Replacement and Re-lubrication:

- Before applying new lubricant after cleaning the bearing surfaces if contamination is found, think about replacing the lubricant.

- Expert Consultation:

- To pinpoint specific sources of contamination and suggest suitable fixes, seek advice from bearing manufacturers or industry professionals.

In summary, addressing lubrication contamination involves a combination of preventive measures, proper lubrication practices, regular maintenance, and expert consultation to ensure the longevity and optimal performance of roller bearings.

2. Corrosion

Corrosion can have a significant detrimental impact on Roller Bearings. When moisture, contaminants, or corrosive substances come into contact with the bearing’s metal surfaces, it can lead to several problems:

- Surface Deterioration: The metal surfaces of the bearing are eroded by corrosion, which results in pitting, roughening, and even deep grooves. As a result, the bearing’s structural integrity is compromised, lowering its ability to support loads and overall performance.

- Increased Friction: The corrosion-induced roughened and uneven surfaces raise friction between the bearing’s parts. Heat produced by this increased friction might cause further damage, overheating, and early failure.

- Abrasive Wear: The byproducts of corrosion and the rough surfaces they produce function as abrasives, hastening wear and shortening the bearing’s life.

- Seal Compromise: Seals and shields intended to keep impurities out of the bearing can become weak or damaged due to corrosion. This lets in more contaminates and worsening conditions.

- Chemical Changes: Corrosion can change the makeup of the greases or lubricants used in bearings, decreasing their efficacy and perhaps resulting in insufficient lubrication.

How to prevent from Corrosion on Roller Bearings

- Prevention: Take action to keep dirt and moisture from getting to the bearings. This may entail appropriate sealing, sufficient storage in climate-controlled settings, and regular maintenance inspections for corrosion indicators.

- Regular Cleaning: Bearings should be regularly cleaned and inspected to get rid of any corrosion products or collected impurities. Use cleaning chemicals that are suitable and won’t exacerbate the harm.

- Corrosion-Resistant Materials: When feasible, choose roller bearings constructed of corrosion-resistant materials, especially in settings where humidity, chemicals, or other corrosive substances are common.

- Proper Lubrication: Use lubricants or greases that give corrosion prevention that are appropriate. These lubricants ought to aid in fending off moisture and preventing the growth of rust.

- Environmental Controls: To reduce the risk of corrosion, keep the working environment within appropriate temperature and humidity ranges.

- Correct Installation: Use the right installation methods to avoid trapping moisture inside the bearing assembly.

- Routine Maintenance: Establish a regimen for regular maintenance that includes cleaning, lubrication, and checks for corrosion.

3. Overloading

Overloading a roller bearing occurs when the applied load on the bearing exceeds its designed capacity. This can have several detrimental effects on the bearing’s performance and overall operation:

- Increased Wear: Overloading places an excessive amount of stress on the bearing’s parts, speeding up wear and fatigue. Pitting, spalling, and other types of surface degradation may happen from this.

- Reduced Lubrication Effectiveness: The additional load may cause the bearing surfaces to distort, decreasing the lubrication’s efficiency. Lack of lubrication exacerbates wear, heat, and friction, further threatening the bearing’s efficiency.

- Increased Heat Generation: higher heat is produced by overloading as a result of higher friction and distortion. Elevated temperatures have the potential to cause thermal damage by accelerating wear and degrading the lubrication..

- Shortened Lifespan: Overloaded bearings often have a considerably shorter operational lifespan. The cumulative consequences of high stress and wear might lead to premature failure.

How to prevent from Overloading on Roller Bearings

- Assessment: Find the underlying reason of the overloading, which may include faulty load estimations, unanticipated load spikes, or modifications to the operational environment.

- Load Correction: Reduce the applied load if at all feasible to stay within the bearing’s rated capacity. This can entail changing the load distribution or mechanism’s design.

- Proper Lubrication: Make sure the bearing gets enough and the right kind of lubricant. By reducing friction and heat production, the bearing’s lifespan is prolonged.

- Redesign: Consider modifying the system to better efficiently accommodate the actual loads and operating circumstances if overloading is a persistent problem.

- Maintenance: Check the bearing often for any symptoms of wear, damage, or overheating. Early detection can enable prompt maintenance or replacement while also assisting in preventing catastrophic failures.

- Training and Guidelines: Make sure individuals in charge of equipment operation and maintenance have the appropriate training so they are aware of load limits and safe operating procedures.

- Use of Load-Carrying Equipment: Consider employing load-carrying equipment like thrust bearings or bigger bearings that can manage the loads more effectively when the load is greater than the bearing’s capacity.

- Consultation with Experts: If you’re unclear of how to handle the overloading problem, think about speaking with bearing specialists or engineers that are knowledgeable in the area.

4. False Brinelling

False brinelling is a phenomenon that can have detrimental effects on roller bearings. It occurs when bearings experience micro-movements, often caused by vibrations or oscillations, even when the bearing’s inner race remains stationary. This continuous motion at the contact points between the rolling elements and the raceway can result in significant wear and damage over time. The term “false brinelling” is used because the wear patterns resemble those of true brinelling, which is caused by heavy static loads, but in this case, the wear is due to repeated small movements rather than heavy loads.

Effects of False Brinelling on roller bearings:

- Wear and Abrasion: The bearing surfaces may become damaged by repetitive contact between the rolling components and the raceway. This may result in a reduction in bearing tolerances, which will impact the bearing’s accuracy and general performance.

- Linear Wear Marks: False brinelling can result in raceway grooves or lines that are indicative of linear wear patterns in the bearing’s axial direction. The operational problems with the bearing may be made worse by these wear signs.

- Lubrication Depletion: Repeated motion can cause the lubrication coating to break down between the raceway and the rolling components, increasing friction and heat production. This may lead to insufficient lubrication and quicker wear.

- Increased Vibration and Noise: False brinelling can worsen with time and affect the performance and efficiency of the machinery as a whole by causing greater vibration and noise in the bearing.

How to prevent from False Brinelling on Roller Bearings:

- Address the Root Cause: Determine the cause of any vibrations or tiny motions that are creating false brinelling, and take appropriate action. This can entail boosting shock-absorbing capabilities in the machinery, lowering vibrations, or improving mounting conditions.

- Proper Lubrication: Make that the bearing is well greased using appropriate anti-wear lubricants. This can lessen the symptoms of fake brinelling by reducing friction and wear.

- Precision Handling: Use precise handling procedures while repairing or installing bearings. In order to avoid contamination during installation, clean all tools and surfaces.

- Bearings Replacement: To restore optimal performance, it could be essential to replace the bearings if the false brinelling damage is severe. To be sure you choose the appropriate bearings for your application, speak with a reliable bearing provider.

- Design Modifications: To lessen the impact of vibrations and tiny motions on the bearings, think about making design changes to the machinery. This can entail improving the bearing installation procedure or installing vibration dampeners.

5. Improper Mounting

Improper mounting of roller bearings can have significant adverse effects on their performance and longevity. Here’s how improper mounting can affect roller bearings and how to address the issue:

Effects of Improper Mounting on Roller Bearings:

- Increased Wear and Friction: An unequal load on the bearing and misalignment might result from improper mounting. Increased wear and friction from this may result in early failure and shorter bearing life.

- Overheating: Inadequate installation might cause uneven loads and excessive heat buildup inside the bearing. This might worsen the grease’s or oil’s ability to lubricate, hastening wear.

- Vibration and Noise: Due to unbalanced stresses exerted on the bearing, incorrectly placed bearings may vibrate and make noise. This can have an influence on the surrounding machinery in addition to the bearing’s performance.

- Reduced Load Capacity: The bearing’s capacity to transport loads might be decreased by improper installation, which would restrict its ability to withstand the anticipated loads without being damaged.

How to prevent from failure from Improper Mounting:

- Removal and Inspection: The first thing to do if you suspect incorrect installation is to remove the bearing and look for evidence of wear or damage from misalignment or uneven loads.

- Proper Tools: To achieve uniform force distribution during installation, use the appropriate bearing mounting equipment, such as hydraulic presses or precision mounting tools.

- Cleanliness: Before installation, be sure that both the mounting surfaces and the bearing surfaces are clear of any dirt or impurities.

- Alignment: To avoid misalignment and unequal loads, precisely align the bearing with its intended location in the assembly.

- Fitting: Place the bearing on the shaft or housing properly. Make sure the bearing is uniformly forced into the shaft when using a press fit, and for interference fittings, make sure the housing is the right size to prevent the bearing from being harmed.

- Temperature Control: Consider employing controlled temperature procedures to inflate or compress components for simpler fitting when there are interference fits.

- Lubrication: To maintain optimal lubrication between the bearing surfaces, use the right lubricant in the right quantity.

- Torque: To hold the bearing in place without causing damage, tighten fasteners to the manufacturer’s suggested torque levels.

- Alignment Check: After installation, run a bearing alignment check to make sure it is positioned and aligned within the assembly properly.

- Training and Guidelines: Make that individuals in charge of installing bearings have the necessary training and adhere to the manufacturer’s suggested policies and procedures.

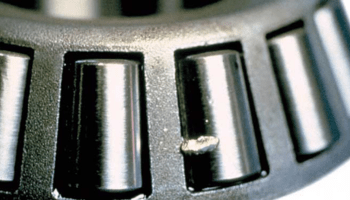

6. Spalling

Spalling is a form of surface damage that can affect roller bearings, particularly their rolling elements and raceways. It refers to the formation of small, localized cracks or flakes on the bearing surfaces, often resulting from repeated rolling contact stress, improper lubrication, contamination, or other mechanical stresses. Spalling can lead to the shedding of metal particles and reduced bearing performance, ultimately impacting the bearing’s operational efficiency and lifespan.

The effects of Spalling on Roller Bearings include:

- Reduced Load-Bearing Capacity: The effective bearing contact surface decreases with increasing spalled patches, which lowers the bearing’s ability to support additional weight.

- Increased Friction and Heat Generation: Spalled areas impart imperfections to the bearing surfaces, increasing friction and generating more heat. This can cause overheating and quicker wear.

- Vibration and Noise: Spalling can disturb the machinery’s smooth functioning and signal the presence of a problem by causing vibration and noise in the bearing.

- Premature Failure: Spalling can advance if it is not treated right away, eventually leading to substantial bearing failure that may harm other parts of the equipment.

How to prevent from Spalling in roller bearings:

- Inspection: Check the bearings for symptoms of spalling on a regular basis, such as pitting, cracking or flaking on the surfaces of the raceways and rolling components.

- Lubrication: Use the specified lubricant kind and amount to ensure optimal lubrication. A protective coating is created by effective lubrication, which lowers friction and lowers the chance of surface damage.

- Maintenance: Implement routine maintenance procedures, such as cleaning and relubrication, to stop pollution from getting within the bearing and causing spalling to worsen.

- Alignment and Installation: When installing the bearing parts, make sure to line them properly to prevent extra strains that can cause spalling.

- Load Management: To prevent excessive stress that might result in spalling, operate the machinery within the bearing’s load capability.

- Vibration Monitoring: Use vibration analysis and monitoring methods to look for early bearing problems, such as spalling.

- Replacement: It is advised to replace the bearing with a new one if the bearing’s performance has been considerably impacted by severe spalling.

From where we should choose the Appropriate Bearing for Your Machinery

Santiniketan Enterprises, also known as SantEnt, has been in operation since 1977. We are known for Distributing high-quality Industrial products to customers in many countries across six continents. We deal in over 50 globally renowned brands which manufacture industrial spares and power transmission solutions like bearing, belts, maintenance products and related accessories

SantEnt is dedicated to providing top-quality products and service to its customers.