Single Row vs Double Row Ball Bearings

A ball bearing is a type of rolling-element bearing that relies on small balls to maintain separation between the inner and outer races. Its main purpose is to reduce rotational friction while providing support for radial and axial stresses. Ball bearings have been in use for many years and find applications in a wide range of devices, from hard drives to skateboards, where they are designed to handle both thrust and radial loads. They are also commonly employed in situations with lower pressures.

The load is transferred from the outer race to the inner race through the balls. The spherical shape of the balls allows for smooth rotation, as they make only minimal contact with the inner and outer races. However, if a ball bearing is not used correctly, it can become a hindrance. Overworking the bearing can lead to deformation of the balls and damage to the bearing due to the limited contact area supporting the load.

Ball bearings are typically manufactured from materials such as chrome steel or stainless steel. In certain consumer applications, glass or plastic balls are also used. They are available in various sizes, ranging from miniature bearings for hand tools to larger bearings for industrial machinery. The load capacity and reliability of ball bearings are key factors to consider when selecting them for specific applications.

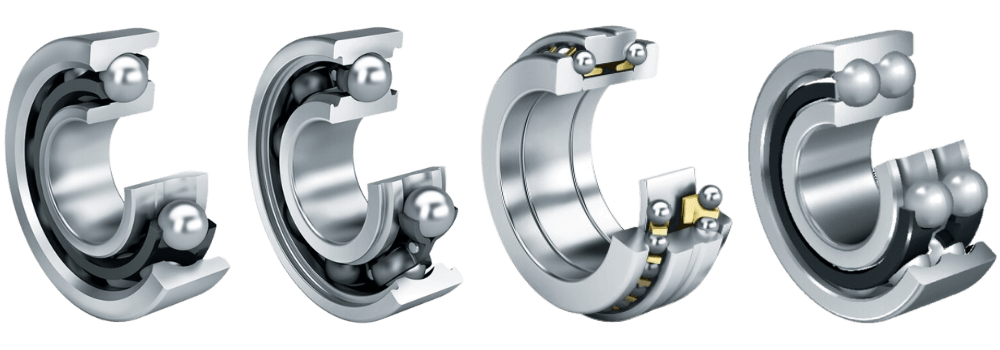

Two Types of Single Row Ball Bearings

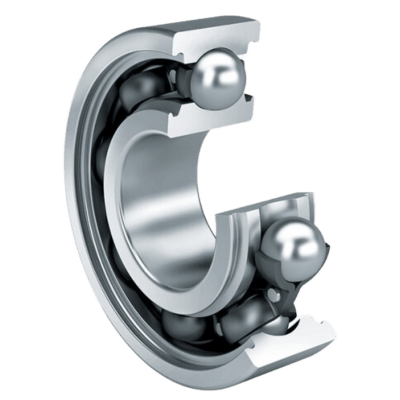

Angular Contact Ball Bearings

Advantages of Single Row Angular Contact Ball Bearings:

- High axial load carrying capacity

- Increased rigidity

- Space-saving design

- High-speed capability

- Versatility

- Ease of installation and maintenance

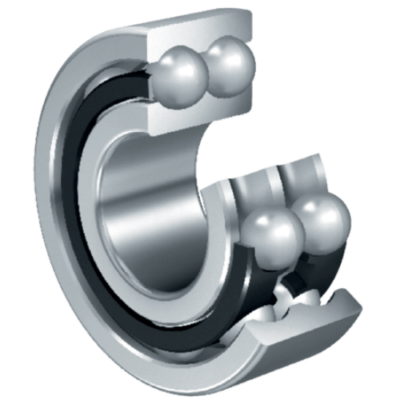

Deep Groove Ball Bearings

Advantages of Single Row Deep Groove Ball Bearings:

- High-speed capability

- Low noise and vibration

- Easy installation and maintenance

- Cost-effective

- Energy efficiency

- Space-saving design

Types of Double Row Ball Bearings

Angular Contact Ball Bearings

Advantages of a Double Row Angular Contact Ball Bearing:

- Increased load-carrying capacity

- Enhanced stiffness and rigidity

- Improved axial and radial rigidity

- High-speed capability

- Versatility in mounting arrangements

- Space-saving design

Deep Groove Ball Bearings

Advantages of Double Row Deep Groove Ball Bearings:

- Increased load-carrying capacity

- Enhanced radial rigidity

- Space-saving design

- Versatility in load distribution

- High-speed capability

- Low noise and vibration

Difference Between Single Row and Double Row Ball Bearings

Single Row Ball Bearing are the most common type of ball bearing. This bearing has one row of rolling parts, with a simplistic construction. They are non-separable, appropriate for high speeds, and durable in operation. They can handle both radial and axial loads.

Double Row Ball Bearing are more robust than single row and can handle higher loads. This type of bearing can take radial loads and axial loads in both directions. It can keep the shaft and housing axial movement within the bearing’s axial clearance. However, they are also more complex in design and require more precise manufacturing tolerances.

Conclusion

Single Row and Double Row Ball Bearings find extensive usage across diverse applications. Single row bearings are typically employed in light-duty scenarios, whereas double row bearings are better suited for heavy-duty applications. Ball bearings play a crucial role as components in various machinery and equipment.

To ensure the proper functioning of bearings, it is essential for them to endure a minimum load, particularly under conditions involving high speeds, strong accelerations, or rapid changes in load direction. The inertial force of the ball and cage, as well as friction in the lubricant, can have a negative impact on the rolling of the bearing, potentially leading to sliding motion between the ball and the raceway, which may cause damage to the bearing.

Selecting the Appropriate Bearing Material for Your Machinery

Santiniketan Enterprises, also known as SantEnt, has been in operation since 1977. We are known for Distributing high-quality Industrial products to customers in many countries across six continents. We deal in over 50 globally renowned brands which manufacture industrial spares and power transmission solutions like bearing, belts, maintenance products and related accessories

SantEnt is dedicated to providing top-quality products and service to its customers.