Advantages of Investing in premium Quality Bearings

Understanding the methods of obtaining top-notch bearings in India is crucial because bearings are precise components with a crucial role in manufacturing processes.

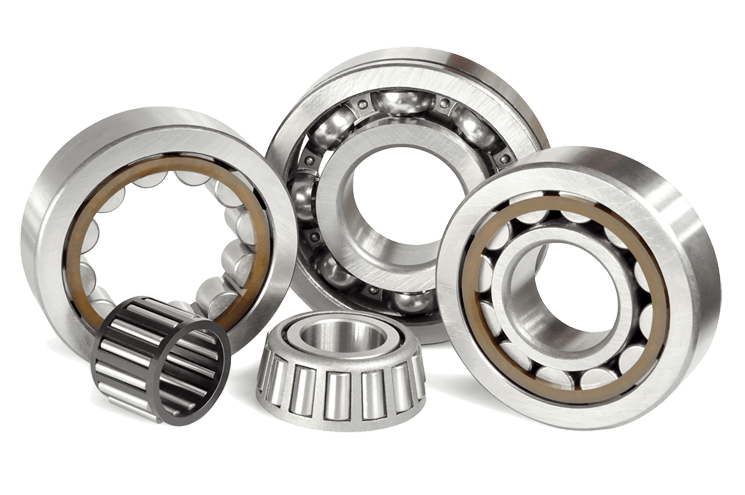

The responsibility of reducing friction among constantly moving parts places significant stress on compact elements such as bearings. Regardless of whether you opt for ball bearings or roller bearings to accommodate your transmission loads, the caliber of your bearings remains indispensable for minimizing operational interruptions and sustaining the smooth operation of your machinery.

As the primary supplier of bearings in India, we have addressed several frequently asked questions regarding the importance of investing in high-quality bearings.

- What Significance Does Investing in High-Quality Bearings Hold?

Comparable to other crucial expenditures made inside your business, top-tier bearings in Singapore are an important investment. The initial investment in quality will pay for itself in terms of the equipment and process maintenance and operational effectiveness.

Quality bearings may result in increased longevity, lower maintenance costs, fewer downtime, and the smooth operation of all related gearbox components, whether it’s in the food production, power generating, maritime industries, or any other industry.

Indeed, possessing high-quality bearings in Singapore, sourced from reputable brands like SKF, Timken, and INA Bearings, can have the following advantages:

- Prevent premature bearing failure

- Decrease total downtime

- Prevent unforeseen shutdowns

- Reduce the necessity for reactive maintenance

- Lower transmission operational costs

- Handle higher transmission loads

- Extend operational lifespan

2.What Are the Ways to Recognize High-Quality Bearings?

Identifying quality bearings can be done through three ways: investing in trusted brands, completing a visual test, and applying the rocking test.

a) Invest in Trusted Brands

Through your chosen bearing provider, you have the opportunity to explore an extensive selection of reputable bearing manufacturers. Whether you’re looking for INA needle bearings or FAG ball bearings, it’s important to assess the average grade of the bearing balls they manufacture and have confidence in the provided quality.

In your quest for dependable brands, it’s crucial to verify whether their products hold ISO certification. The International Organization for Standardization (ISO) is an entity dedicated to ensuring the quality and standardization of products such as bearings. If the bearing bears the appropriate certification, it should feature an “ISO” label followed by a series of numerical codes signifying the certification.

b) Complete a Visual Test

Conducting a visual examination of a bearing while wearing clean gloves and utilizing a magnifying glass (as required, based on the bearing’s size) can aid in evaluating its grade and overall quality. This inspection is essential to confirm that the bearing has not suffered damage resulting from a compromised seal or improper lubrication. During the inspection, be sure to look for the following indicators:

- Abnormal sounds emanating from the bearing

- General or localized discoloration

- Flaking observed on any rolling element (ball or roller)

- Rust evident on the inner ring, outer ring, and cage

- Presence of cracks in the bearing

- Indications of misalignment during rotation

- Accumulation of dirt or debris in the vicinity of the bearing

- Insufficient lubrication

- Noticeable heat generated by the moving bearing

c) Apply the Rocking Test

The rocking test serves as a valuable inspection technique to ensure the sustained quality of the bearing ball grade throughout its operational lifespan. At times, a bearing might initially appear to be of high quality and in line with its grade, but factors like usage or improper handling during shipping and storage can lead to deterioration. By subjecting your bearing to a rocking test, you can proactively safeguard its durability and receive early indications of undesirable wear.

To conduct a rocking test, position the bearing horizontally and exert pressure on both its top and bottom surfaces. This action will induce a rocking motion, from which the name is derived, and reveal any motion or play within the wheel or other constituent parts of the bearing.

Such movement serves as an indicator of subpar quality and signals the need to turn to your trusted Singapore bearing supplier for a reliable power transmission component for your machinery.

3. What are Bearing Ball Grades?

Procuring a top-notch bearing from a reputable manufacturer or supplier comes with the added benefit of receiving a bearing ball grade, which serves as an indicator of the bearing’s quality and potential lifespan.

These grades adhere to internationally recognized standards like those set by the American Bearing Manufacturers Association (ABMA) and categorize bearing ball grades on a scale ranging from 2000 to 3. In this context, a lower number indicates higher precision and quality of the ball, with designations ranging from “G2000” to “G3.”

The grade is a measure of the ball’s surface precision and is determined by assessing the greatest possible distance between two points on the ball in relation to the closest possible distance.

When seeking quality bearings in Singapore, it’s advisable to opt for those with a high grade (low number), as this indicates that the balls within your bearing are exceptionally precise, smooth, round, and less prone to experiencing friction during movement. This translates to smoother power transmission and extended longevity for your ball bearing.

4. What is The Best Materials Used to Make Quality Bearings?

There are different types of bearing materials used to manufacture ball bearings and roller bearing for industry:

- Carbon Steel

- Chrome Steel

- Stainless Steel

- Ceramic

- Polymer Plastic

- Hybrid

Each has their own benefits and uses within power transmission and effective longevity in friction-reduced movement. However, high-quality bearings manufactured by pioneers such as SKF, Timken and INA bearings are often made of chrome steel, stainless steel or ceramic due to their hardiness and high-load capacity from both axial and radial loads.

From Where you should buy high quality bearings?

Santiniketan Enterprises, also known as SantEnt, has been in operation since 1977. We are known for Distributing high-quality Industrial products to customers in many countries across six continents. We deal in over 50 globally renowned brands which manufacture industrial spares and power transmission solutions like bearing, belts, maintenance products and related accessories

SantEnt is dedicated to providing top-quality products and service to its customers.

Contact us now for the Best Prices & Ready Stock!